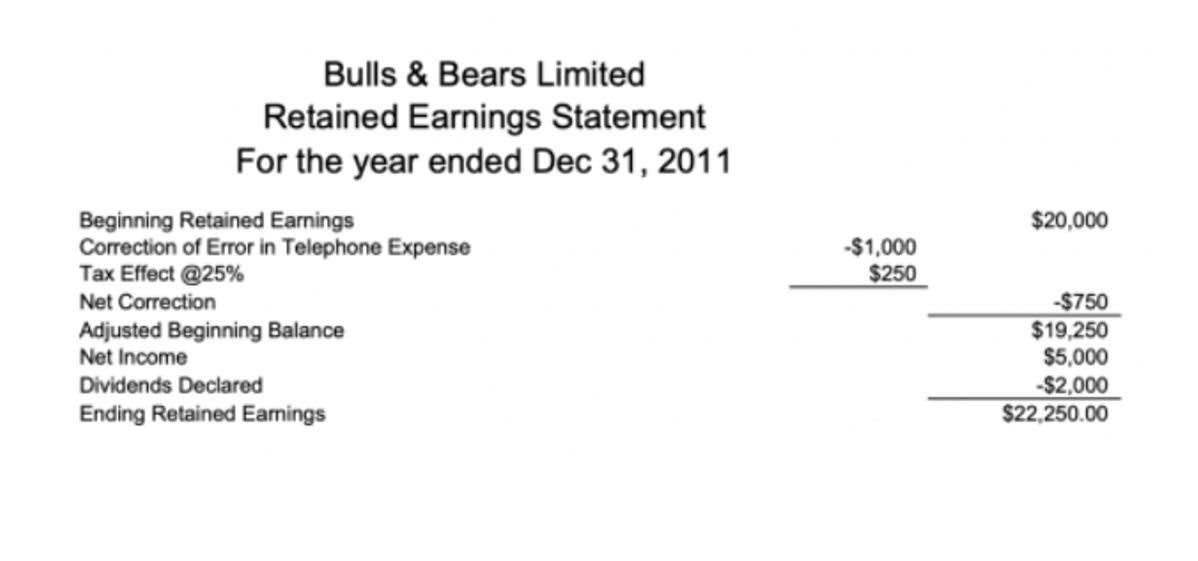

Sales of each product have been strong, and the total gross profit for each product is shown in Figure 6.7. Using the Solo product as an example, 150,000 units are sold at a price of $20 per unit resulting in sales of $3,000,000. The cost of goods sold consists of direct materials of $3.50 per unit, direct labor of $10 per unit, and manufacturing overhead of $5.00 per unit. With 150,000 units, the direct material cost is $525,000; the direct labor cost is $1,500,000; and the manufacturing overhead applied is $750,000 for a total Cost of Goods Sold of $2,775,000. If the predetermined overhead rate calculated is nowhere close to being accurate, the decisions based on this rate will definitely be inaccurate, too.

- Fixed costs are those that remain the same even when production or sales volume changes.

- Here, according to this method of overhead absorption, $5 per unit will be taken as factory overhead.

- A predetermined overhead rate is defined as the ratio of manufacturing overhead costs to the total units of allocation.

- For example, the total direct labor hours estimated for the solo product is 350,000 direct labor hours.

- This information can help you make decisions about where to cut costs or how to allocate your resources more efficiently.

Overhead Rate Formula and Calculation

A good rule of thumb is to ask yourself if the cost will be incurred regardless of how much product you’re making. But before we dive deeper into calculating predetermined overhead, we need to understand the concept of overhead itself. A financial professional will offer guidance based on the information provided and offer a no-obligation call to better understand your situation.

Introduction to Overhead Rate Calculation in Accounting

The overhead rate is a cost added on to the direct costs of production in order to more accurately assess the profitability of each product. In more complicated cases, a combination of several cost drivers may be used to approximate overhead costs. The allocation of overhead to the cost of the product is also recognized in a systematic how to calculate predetermined overhead rate per direct labor hour and rational manner. The overhead is then applied to the cost of the product from the manufacturing overhead account. The overhead used in the allocation is an estimate due to the timing considerations already discussed. For example, the recipe for shea butter has easily identifiable quantities of shea nuts and other ingredients.

Total the Overhead Costs

The overhead rate is a cost allocated to the production of a product or service. Overhead costs are expenses that are not directly tied to production such as the cost of the corporate office. To allocate overhead costs, an overhead rate is applied to the direct costs tied to production by spreading or allocating the overhead costs based on specific measures. Properly calculating and applying overhead rates is an important accounting process for businesses to absorb indirect costs into their job costing system and product pricing.

Compare Overhead to Sales

Small companies tend to use activity-based costing, whereas in larger companies, each department in which different processes of production take place typically computes its own predetermined overhead rate. A predetermined overhead rate is an allocation rate given for indirect manufacturing costs that are involved in the production of a product (or several products). This ratio signifies that every dollar of machine-hour costs generates $1.25 in total overhead costs. The overhead rate can be determined by dividing the total estimated overheads of the cost center or job by the total estimated units of output.

Overhead Rate Meaning, Formula, Calculations, Uses, Examples

- Fixed overhead costs, such as rent and salaries, remain constant regardless of production levels.

- For example, overhead costs may be applied at a set rate based on the number of machine hours or labor hours required for the product.

- To calculate how your overhead rate, divide the indirect costs by the direct costs and multiply by 100.

- Sandra’s areas of focus include advising real estate agents, brokers, and investors.

- Now, let’s look at some hypothetical business models to see actual use-cases for predetermined overhead rates.

By lowering the proportion of overhead, a business can gain a competitive advantage by increasing the profit margin or pricing its products more competitively. If, however, it falls short of the actual overhead, the difference is known as under-applied overhead. This method is usually applied in cases where labor is the main factor in production. It is also applied when the quality, skill, and gender of employees do not differ significantly. Ideally, the quantity and cost of materials in each product are uniform, and processing is also uniform. This application of overheads is called absorption, which can be defined as the charging of overheads to production.

- This process contrasts with traditional, subtractive manufacturing methods, which often involve cutting away material to achieve the desired form.

- In an automated factory, you would be likely to base overhead allocation on machine hours instead.

- Following expense optimization best practices and leveraging technology keeps overhead costs in check.

- Since the numerator and denominator of the POHR formula are comprised of estimates, there is a possibility that the result will not be close to the actual overhead rate.

- A predetermined overhead rate is calculated at the start of the accounting period by dividing the estimated manufacturing overhead by the estimated activity base.